Mammut 2024 Responsibility Report Reveals Circularity Milestones - 14,928 Repairs & 12 Tons Of Repurposed Rope

Mammut Sports Group AG is pleased to announce its key sustainability achievements in the 2024 Responsibility Report. The report highlights the gradual expansion in repair services, the introduction of circular innovation LOOPINSULATION, and advancements in more sustainable material sourcing.

Key highlights from the report:

- 14,928 Repairs in 2024: Mammut’s global repair network extended the life of nearly 15,000 products, a notable increase over last year and a testament to our commitment to reducing waste and promoting product longevity.

- 12 Tons of Rope Repurposed: The launch of LOOPINSULATION, an insulation material made from rope production offcuts, transformed 12 tons of factory waste into high-performance insulation—cutting emissions by 48% compared to virgin polyester.

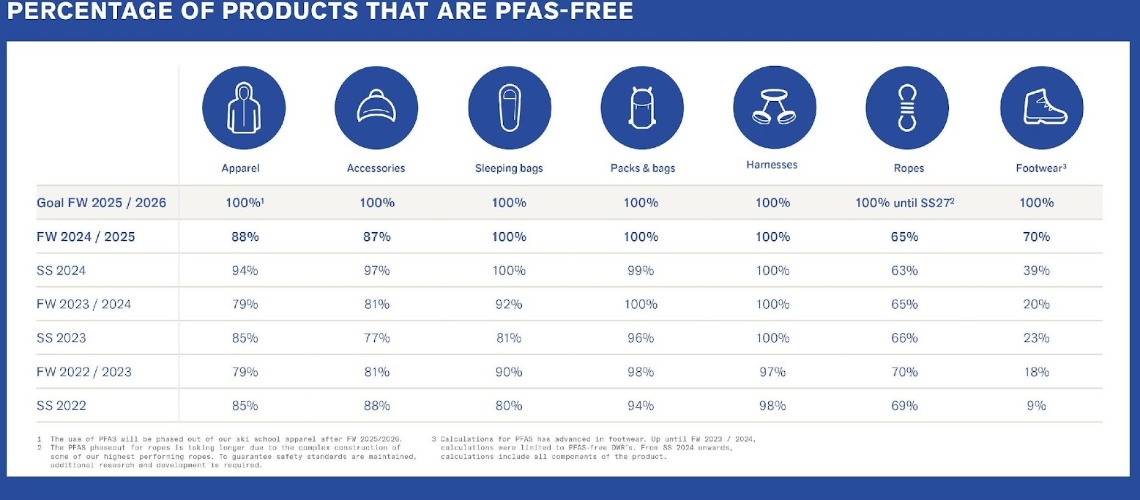

- PFAS-Free Progress: By Spring/Summer 2024, 100% of Mammut sleeping bags and harnesses, and 94% of apparel, are PFAS-free, with a clear roadmap to eliminate PFAS from all products by 2026.

- Sustainable Materials: Mammut now uses recycled polyester in the majority of its products and is on track to reach 95% recycled polyester usage by 2025. Organic cotton is found in 88% of apparel, all certified to the highest standards.

- Decarbonization Efforts: Despite a 6.5% increase in total carbon footprint due to business growth, Mammut reduced its carbon intensity by 0.3% and is investing in high-quality carbon removal projects, aiming to decarbonize 90 tons of CO2 by 2025.

These achievements reflect Mammut’s ongoing leadership in circularity, responsible material sourcing, and climate action.

While the company's total carbon footprint grew by 6.5% in 2024—mainly attributable to business growth—the carbon intensity declined by 0.3%, demonstrating operational efficiency and responsible practices.

14.9K repairs: Empowering longevity

Long-term use of outdoor equipment is the easiest way to reduce its environmental footprint. While Mammut stands behind the durability of its products, damage can occur. The 2024 Responsibility Report shows that Mammut's global network of in-house repair specialists and third-party partners repaired an estimated 14,928 products globally in 2024. This figure represents items that were prevented from being disposed of prematurely and demonstrates the company's ongoing commitment to extending the life of outdoor equipment and minimizing waste.

This represents a notable increase from 13,466 repairs in 2023, highlighting a steady upward trend in Mammut's repair initiatives. While 73% of repairs were completed in continental Europe and the UK, 27% were handled by third parties in North America, China, Japan, and Norway.

LOOPINSULATION: 12 tons of repurposed rope

A special highlight of 2024 is the launch of Mammut LOOPINSULATION: a pioneering insulation material created from offcuts generated during industrial rope production. This innovative initiative transforms factory waste into valuable, high-performance insulation. In 2024, LOOPINSULATION repurposed 12 tons of polyester rope production waste, resulting in insulation that produces 48% fewer carbon emissions compared to conventional virgin polyester. This technology not only significantly repurposes waste and reducesemissions but also sets a new benchmark in sustainable product design within the outdoor industry. LOOPINSULATION is a vivid illustration of how Mammut's focus on circularity and resource efficiency is driving material innovation across product lines.

Responsible material management

Innovations such as LOOPINSULATION form an integral part of Mammut's sustainable materials management. The 2024 Responsibility Report highlights Mammut's increased use of sustainable materials, with a strong focus on recycled and certified fibers: Notably, recycled polyester is used in the majority of Mammut's apparel, sleeping bags, backpacks, and now even in harnesses, with a stated goal of reaching 95% across all polyester products by 2025. Recycled polyamide is—despite its bigger challenges compared to other materials—also gaining ground, especially in new collections. Organic cotton is found in 88% of Mammut's apparel, all of which is certified to the highest standards, with the company aiming for full adoption by 2025.

100% PFAS-free sleeping bags and harnesses

Mammut has set clear timelines for the complete phase-out of PFAS (per- and polyfluoroalkyl substances) across all product categories by FW 2025/2026 (ropes by SS27) and is dedicated to educating consumers about the care and benefits of PFAS-free alternatives. PFAS are used in outdoor clothing to give products water repellency, as well as stain and grease resistance. In recent years, their use has been reassessed due to their negative impact on both human health and wildlife.

The 2024 Responsibility Report documents Mammut's accelerated move away from PFAS in product lines. By the Mammut Spring/Summer collection 2024:

- 94% of apparel is PFAS-free, up from 85% in summer 2023 and 79% in fall/winter 22/23.

- 97% of accessories are PFAS-free, compared to 77% in summer 2023.

- 100% of sleeping bags and harnesses have achieved full PFAS-free status.

- 99% of packs and bags and 63% of ropes are PFAS-free, with continued improvements underway.

Unlike their predecessor, PFAS-free Durable Water Repellents (DWR) are not yet grease or wash resistant. As a result, Mammut aims to increase consumer education around washing and re-proofing their gear.

Heiko Schäfer, CEO of Mammut Sports Group AG, "We are proud of the achievements we have made in repairs, responsible materials, and our ambitious PFAS-free targets. The introduction of LOOPINSULATION demonstrates how creative thinking and a commitment to circularity can lead to tangible, industry-leading solutions. These are a testament to the collective efforts and contributions of our colleagues, partners, and the broader Mammut community. They reflect our journey and the strides we have made toward becoming a more responsible actor in the outdoor industry. We have come far, but there is still much to do."

Do our best—remove the rest: Raising awareness for carbon removal

Decarbonization remains a central pillar of Mammut's sustainability journey. Despite a 6.5% increase in total carbon footprint in 2024, which can be attributed to growth in business activities, the commitment to reducing emissions intensity has shown results: carbon intensity per unit of economic output fell by 0.3%. These improvements are backed by robust initiatives aligned with the "Do our best—remove the rest" strategy, which prioritizes operational efficiency, the use of renewable energy, and innovation in product design to minimize emissions at every step. For residual emissions that cannot yet be eliminated, Mammut invests in high-quality carbon removal projects. To educate on carbon removal strategies, Mammut and Klimate released a film in 2024 featuring elite climber Adam Ondra and the carbon removal processes at CopenHill while pledging to decarbonize 90 tons of CO2 by 2025.