KTI-Plersch Kaltetechnik Promotes Container-sized All Weather Snow Systems

White ski slopes and cross-country ski trails despite summer temperatures: the all-weather snow systems from the Swabian cooling company make it possible

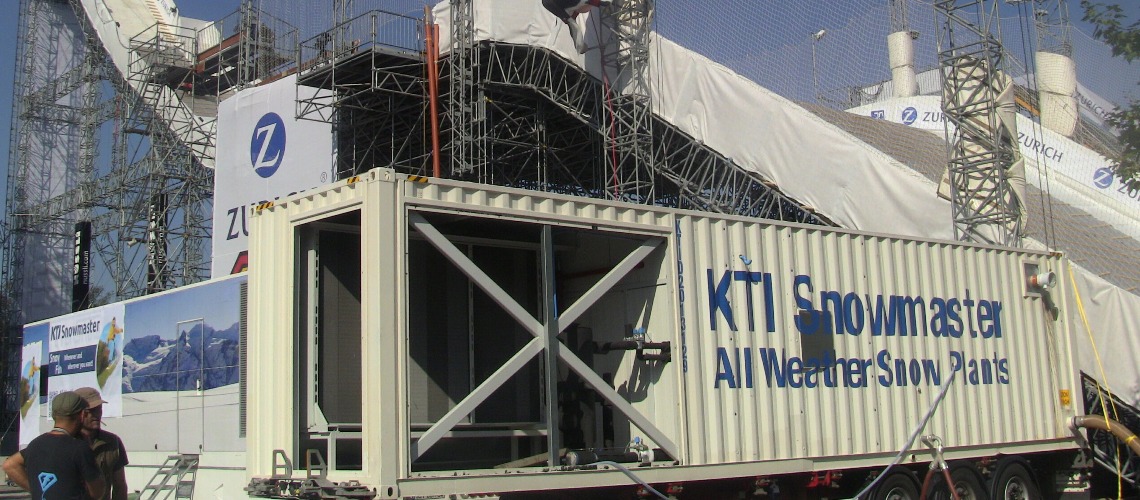

The rising average temperature in the winter months means that there is increasingly no snow, even in high-altitude winter sports areas. This presents competition organizers and ski slope operators with a logistical and economic challenge. Because often the routes can only be prepared with the help of artificial snow in such a way that they offer recreational athletes safe snow fun and ski sports associations and organizers can guarantee competitions under regular conditions. The refrigeration technology specialist KTI-Plersch Kältetechnik from Balzheim in Swabia, which has more than 35 years of experience in the development of various refrigeration systems, offers with the snowPRO a mobile solution in container size, which allows white cross-country ski runs and non-slip downhill slopes even at positive temperatures and regardless of the weather guaranteed. The biggest advantage: Since the snow contains more energy and is more compact than that from ordinary snow cannons, it stays in place longer and is not negatively influenced by the climate or wind. This enables effective snowmaking on the slopes.

When Felix Neureuther won the World Cup parallel slalom on New Year's Day 2013 on Munich's Olympiaberg in front of the impressive backdrop of the Olympiapark, it was already clear that holding the race regularly in the middle of the

Bavarian capital was no easy task. But nobody expected that due to a lack of snow it would be the second and last slalom for the time being. In 2015, the German Ski Association (DSV) finally decided to end the spectacular competition.

Bavarian capital was no easy task. But nobody expected that due to a lack of snow it would be the second and last slalom for the time being. In 2015, the German Ski Association (DSV) finally decided to end the spectacular competition.Since then, however, the lack of snow has not only caused headaches for organizers in Munich or slope operators in the foothills of the Alps. Anyone who regularly hits the slopes during the cold months or follows competitions in sports that rely on snow - whether it's biathlon, cross-country skiing, Nordic combined, ski jumping or even alpine racing - should have already noticed that it used to be so dreamy white scenery has given way in many places to muddy white snow bands in the midst of a green-brown landscape. In recent years, reports have also increased that international competitions in various disciplines have been relocated to other venues with more snow-sure conditions or even canceled entirely because the white element was missing or the weather would not have made it possible to race under normal conditions.

Conventional snow cannons and lances can only be operated at temperatures below freezing

Organizers and piste operators have long used various options to artificially snow their slopes and cross-country ski runs. However, the procurement or production of artificial snow often involves a great deal of effort and is subject to certain conditions. "The production of snow using a snow cannon, for example, only works if the relationship between outside temperature and humidity - the so-called wet bulb temperature - is within a certain range," explains Tobias Heier, Product Manager at KTI-Plersch Kältetechnik GmbH. "Depending on the humidity, the ambient temperature must be around the freezing point, and even well below it if the humidity is high." But especially in the transitional periods, When many winter sports enthusiasts hope for the first or last possible downhill run on slopes that are not quite as crowded in the ski season or when international competitions often take place well into March and April, such conditions are rarely the case. Some organizers therefore have tons of snow delivered from snowy areas and then store it in tents or halls. But this procedure is associated with a high logistical and financial effort - not to mention the high CO2 pollution caused by transport, storage and cooling. Ski lift operators also have to resort to tricks to keep the slopes open for winter holidaymakers for as long as possible without losing sight of the cost-benefit ratio.

The all-weather snowPRO snow systems from KTI offer a remedy - even in tropical temperatures

In Swabian Balzheim, the headquarters of the family-run company KTI-Plersch Kältetechnik, on the other hand, a completely different approach was chosen. Because the company has more than 35 years of experience in an area that at first glance has nothing to do with the production of ordinary snow for ski slopes and cross-country ski trails: it develops and implements industrial refrigeration systems, for example to cool food or concrete. The special thing about it: All systems are installed by KTI-Plersch in a container, just as they are used on ships, freight trains or trucks for the delivery of various goods. This means that the refrigeration systems can be easily transported to the place of use and put into operation quickly. KTI-Plersch is also increasingly relying on the use of natural refrigerants, which have a positive effect on the environment as well as on the energy efficiency of the snow systems.

When it comes to snow production, the company now benefits from years of experience with CO2-neutral refrigerants that are available worldwide. Because with their help, ice can be made from water in an environmentally friendly and highly efficient way, which is then processed into artificial snow and transported outside using compressed air. This simple principle and the practical container size of the CTI systems are brought together in the so-called snowPRO. "The advantage of our snow is that it has a low surface-to-volume ratio and can therefore store the cold well," reports Heier.

Thanks to the weather-independent chiller, snow production is possible at summer outside temperatures, even if operators have to reckon with the snow melting quickly without protective measures. If the specially adapted snowPRO systems from KTI-Plersch are used for this, the snow can be reliably produced even in tropical temperatures or an ambient temperature of up to +35 °C. Operators of indoor ski halls in particular benefit from these models.

Since the market launch in 2013, 71 systems have been in use worldwide

Since the development of the first machine for making snow at positive temperatures, more than 70 systems have been put into operation worldwide at different altitudes and climatic zones. In addition to downhill ski slopes, biathlon arenas or winter sports training centers in various low mountain ranges in Europe, Oceania and North America, the systems are also used in indoor ski halls in Thailand or Indonesia as a supplement to snow cannons. In this way, the residents should be able to enjoy skiing in the snow even when the outside temperatures are tropical. In addition, KTI-Plersch rents out the facilities for special events and sporting events such as World Cup races or jumping. All that is required for operation is a solid foundation and an appropriate power and water connection.

Tailor-made snow technologies ensure high efficiency

Depending on snow requirements, one or more 40' containers are used. At least 100 m³ of snow can be produced with a 40' container per day, with two containers it is already up to 210 m³. In the future, however, the experts for refrigeration technology will also be offering compact systems with a daily capacity of 70 m³ in 20' containers. “These compact snow machines are quick and easy to transport and install, so they can be placed in places that are difficult to access. This type of system is also ideal for renting out for special events,” says Caroline Walleter-Plersch, CEO. Here, the so-called flake ice is produced. The water freezes on the inside of a cylindrical ice maker and is removed by a rotating knife roller.

Variants with an even higher power density of up to 320 m³ per day (two containers, each 40') have been available since 2021. These are based on a different type of ice production, in which so-called plate ice is produced even more energy-efficiently. KTI implemented the idea of using slab ice in technical snowmaking with the ski lift operator Florian Leber from Winterberg in the Sauerland region. In the winter of 2020/2021, the first prototype was successfully tested on one of its ski slopes. “The flat ice completely exceeded my expectations as the operator of such a system. Thanks to the residual moisture, I can also prepare steep sections on frosty nights because the ice binds very well,” reports Florian Leber. “Once the originally coarser structure has been treated with a snow groomer, the skier can no longer tell any difference from normal snow. At the same time, the snow on this southern slope is very resistant to solar radiation. With a similar power consumption and the same installation space, this system produces about 30 percent more ice than the flake ice machines that I have been using on the neighboring slope for several years. So I have the optimal solution for every slope,” adds Leber.

Depending on the slope, the period in which snow is to be made and personal preferences, the ski resort operators can freely choose the right product from flake ice and plate ice technology.

Snow for every requirement

Regardless of the technology used to make the snow, consistency plays a particularly important role for slope operators as well as for professional athletes and their ski technicians. Here, too, the systems from KTI-Plersch offer advantages. "Our snow is usually a bit denser than the snow from ordinary snow cannons," explains Tobias Heier. "That means it stays in place and isn't blown away so easily, so that in the end less snow is needed to be able to prepare the slope adequately." Slopes prepared with ordinary technical snow from lances or fan guns, which is beneficial for ski technicians and athletes. In general, thanks to some optimizations since the systems were launched in 2013, the snow can now be brought to the desired consistency even more precisely and both small, dry and moist particles can be produced to cater to every athlete's heart.

In the meantime, KTI-Plersch has adjusted well to the needs of operators of ski slopes and winter sports centers. "Instead of looking up at the sky every day and waiting for the first snowflakes to fall from the sky, slope operators can now easily and efficiently take additional measures to be able to operate slopes beyond the main season or to ensure that events can be held, completely regardless of the prevailing ambient temperature,” concludes Caroline Walleter-Plersch. produce dry as well as wetter particles to accommodate every athlete's heart.

KTI-Plersch Kältetechnik GmbH was founded by Rupert Plersch in 1986 and is now being continued by his daughter Caroline Walleter-Plersch. The CTI currently employs 160 people at eight locations. The roots of the company go back to Richard Plersch senior, who started designing and producing components and systems for refrigeration technology back in 1923. Today, the traditional company is the world's leading manufacturer of refrigeration systems, which are not only used to produce technical snow, but also to cool concrete, chemicals, food and beverages and mines. KTI always focuses on customer-specific turnkey solutions. In addition to special systems for industrial refrigeration, these include ice systems and ice storage with ice rakes, ice transport and weighing systems, Slurry ice systems, liquid chillers, cold air, hot air and hot water systems as well as combined cooling and heating solutions are part of the KTI portfolio.

A special feature of the modularized systems is the assembly in converted shipping containers or on frames that are manufactured in Germany. This enables cost-effective transport and quick commissioning at the customer's site. KTI-Plersch Kältetechnik GmbH is based in Balzheim, Baden-Württemberg, where all the systems are also produced. There are branches and service points in several countries for worldwide sales. A special feature of the modularized systems is the assembly in converted shipping containers or on frames that are manufactured in Germany. This enables cost-effective transport and quick commissioning at the customer's site. KTI-Plersch Kältetechnik GmbH is based in Balzheim, Baden-Württemberg, where all the systems are also produced. There are branches and service points in several countries for worldwide sales. A special feature of the modularized systems is the assembly in converted shipping containers or on frames that are manufactured in Germany. This enables cost-effective transport and quick commissioning at the customer's site. KTI-Plersch Kältetechnik GmbH is based in Balzheim, Baden-Württemberg, where all the systems are also produced. There are branches and service points in several countries for worldwide sales.